ABOUT MAXTECH VEHICLE

Maxtech Vehicle, established in 2005, is a leading Chinese manufacturer specializing in semi-trailers. With a commitment to innovation and quality, we combine advanced technology with exceptional craftsmanship to produce

reliable and high-peformance vehicles. Our dedicated team of R&D, production, and sales professionals ensures that we continuously meet the evolving demands of the global market. At Maxtech, we believe in driving progress through technology and building products that stand the test of time.

PRODUCTION EQUIPMENT &TECHNOLOGY

Laser Cutting

Greatly improved cutting precision and overall efficiency through advanced technology and automated processes resulting in higher productivity and quality output.

CNC Plasma Cutting Machine

The CNC Plasma Cutting Machine offers high-speed, precise cutting of metal sheets and components. It uses advanced CNC technology to achieve intricate cuts with minimal waste,improving efficiency and productivity. Ideal for complex shapes and large volumes, it ensures high accuracy in the manufacturing process.

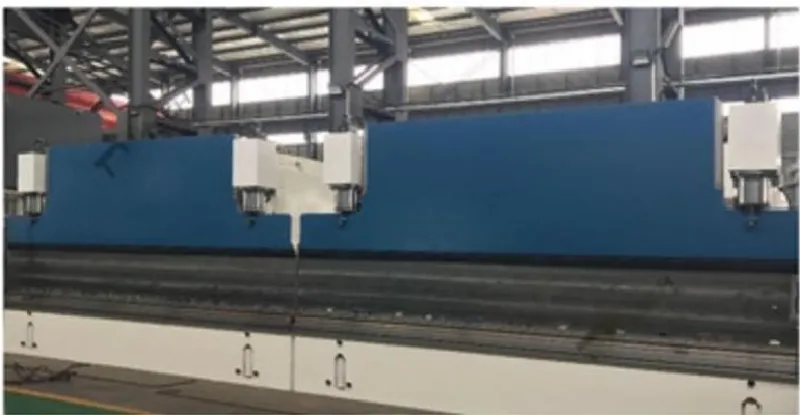

3000t x14m Large CNC Bending Machine

The 3000t Large CNC Bending Machine boasts a maximum working area of 14 meters,enabling precise and efficient bending of large components.Its advanced CNC technology ensures high accuracy and consistency in the bending process,optimizing production efficiency.

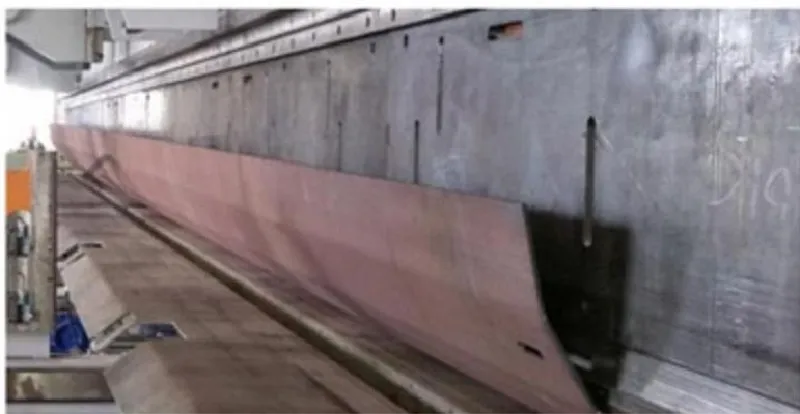

3000t x9m Large CNC Bending Machine

This machine allows for the car body to be formed in one continuous bend without the need for welding.The result is a high-strength, seamless structure,enhancing the overall durability and performance of the product.

Robot Welding

Robot Welding utilizes high-performance arc sensing technology to track weld offset in real-time.This advanced technology significantly improves the accuracy of each weld,ensuring high-quality and consistent results.

Robot Welding

By continuously monitoring the welding process,Robot Welding enhances overallwelding quality, reduces defects, and boosts production efficiency.This results in stronger, more reliable joints for each component, meeting the highest standards of precision.

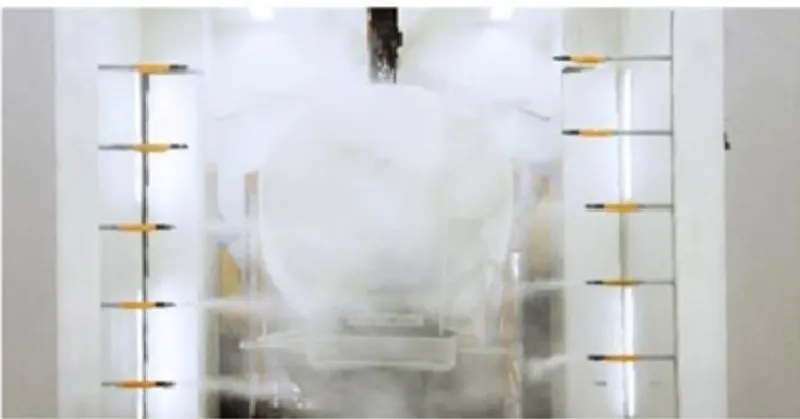

Cleaning and Leaching

Cleaning and leaching remove impurities to enhance quality and durability.

Silane Chemical Pretreatment

This process prepares metal surfaces with a silane-based coating,improving paint adhesion and corrosion resistance. It is an eco-friendly alternative to traditional pretreatment methods,ensuring long-lasting durability.

KTLProcess

This advanced coating method replaces traditional painting techniques,greatly improving corrosion resistance talso ensures zero VOC emissions, offering an environmentally friendly and sustainable solution for coating applications.

Eco-friendly Zero Emission Coating Line

This environmentally friendly coating line ensures zero emissions, creating a pollution-free process while providing high-quality finishes that enhance durability.

Powder Coating

This coating method is versatile,offering various colors and textures for different applications.Its eco-friendly, zero-emission nature makes it a sustainable choice, delivering superior performance while reducing environmental impact.

Powder Coating

Powder coating is a high-efficiency process that provides excellent corrosion resistance,withstanding up to 2000 hours of salt spray. It ensures a durable and uniform finish,ideal for harsh environments.

High Temperature Curing

The process uses elevated temperatures to harden coatings and finishes,ensuring optimal durability and performance. It guarantees a uniform,strong surface, enhancing the overallquality and longevity of the product

Forced Cooling

This step helps solidify the coating efficiently, ensuring uniformity and preventing defects like cracking or warping. It improves the quality,durability, and strength of the final product.

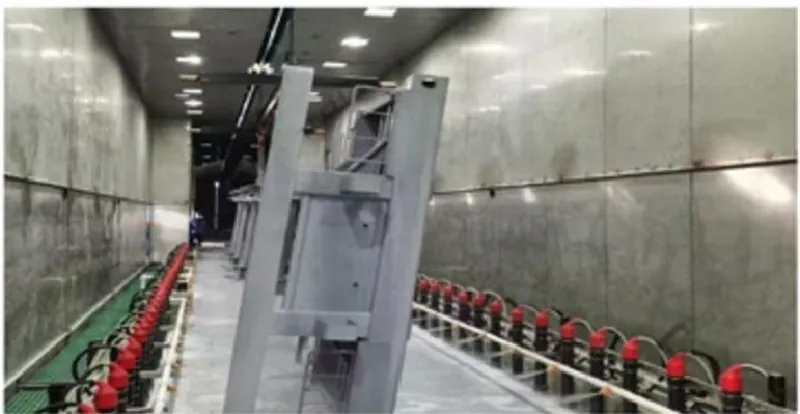

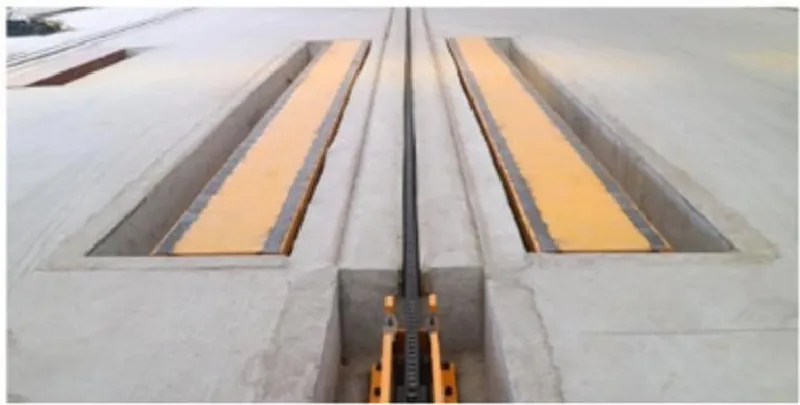

Transmission Chain&Lifting Platform

This system uses a transmission chain and lifting platform to efficiently move heavy components during assembly. It enhances workflow precision and reduces manual handling.

Car Closing Clamping Tooling

This tool is used to securely clamp car body components during the assembly process.It ensures precise alignment and holds parts in place,improving accuracy and efficiency during car body closure.

Transmission Chain &Lifting Platform

Integrated with an automated warehouse and advanced assembly lines,the digitalized process enhances precision and efficiency at every stage.

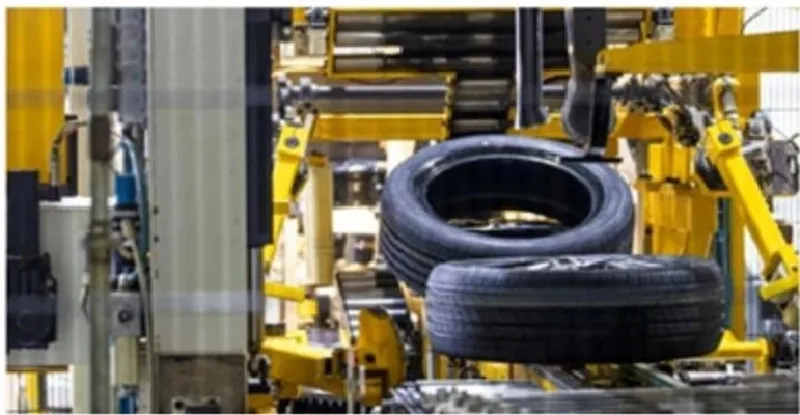

Digitalized Assembly

This approach accelerates production,minimizes errors, and ensures consistent quality,meeting the demands of a dynamic global market.